Ultrasonic Applications

Download our FREE Ultrasonic Application Whitepaper!

When carbon is the contaminant, special cleaning problems may be encountered. Removing carbon from filter media can be accomplished to varying degrees by physical and/or chemical means.

- See the available cleaning tools are chemical and physical processes, which are typically used in combination.

- Learn about the steps to determine ultrasonic applications for gross contaminant removal.

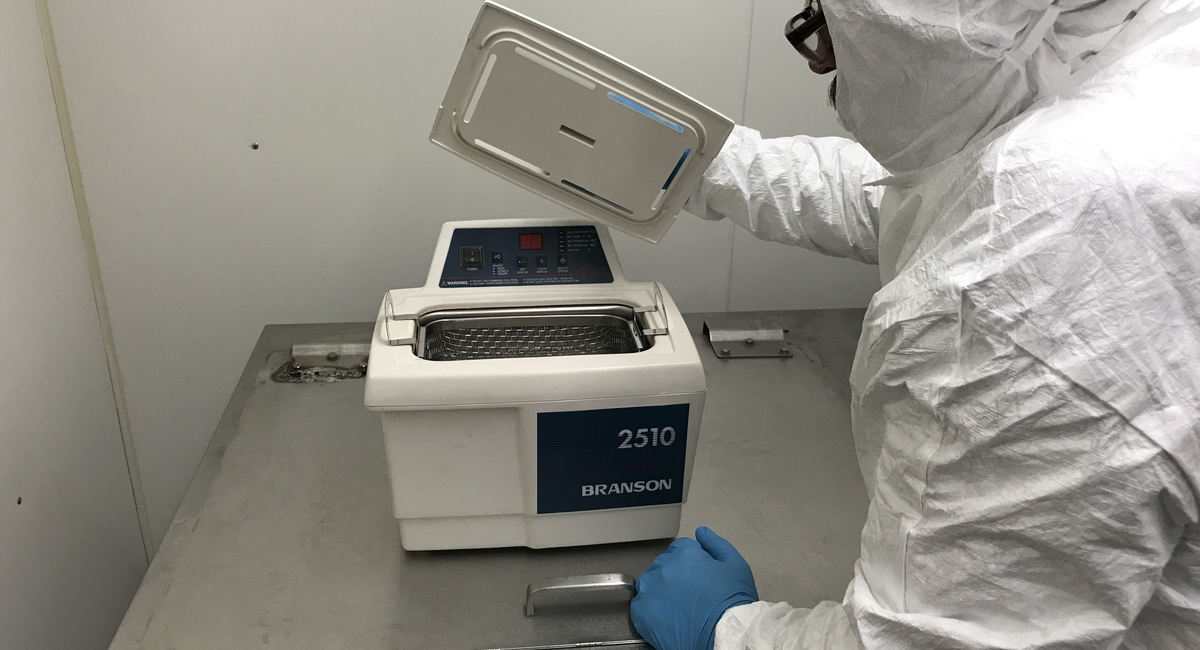

- Understand how ultrasonics can be used in cleaning applications for screens and spinnerets.

Introduction

In providing contract-cleaning services, many different types of contaminated parts arrive for cleaning. Once onsite, the parts must be evaluated to determine the optimum cleaning process in terms of effectiveness of cleaning and without damage to the parts. The available cleaning tools are chemical and physical processes, which are typically used in combination.

Regardless of the type of part and contaminant, the cleaning procedures are usually broken down into gross contaminant removal, polishing, rinsing, and drying. Although drying is an essential and important part of most procedures, the primary focus of this discussion is cleaning; therefore, drying processes will not be discussed.

When developing a cleaning procedure, understanding how the cleaning tools in Figure 1 can be used, or should not be used, will determine whether the process results in effective cleaning and/or damage to the parts being cleaned. During gross contaminant removal, it is necessary to realize that this step should be designed to remove large amounts of mainly exterior contamination. The final polishing steps can then be used to remove attached scale and, possibly, hidden, microscopic residuals. Regardless of the methods and cleaning tools used, rinsing away contaminants as they are loosen and/or released from the part is essential.