Laboratory Filter Testing and Evaluation

How it works

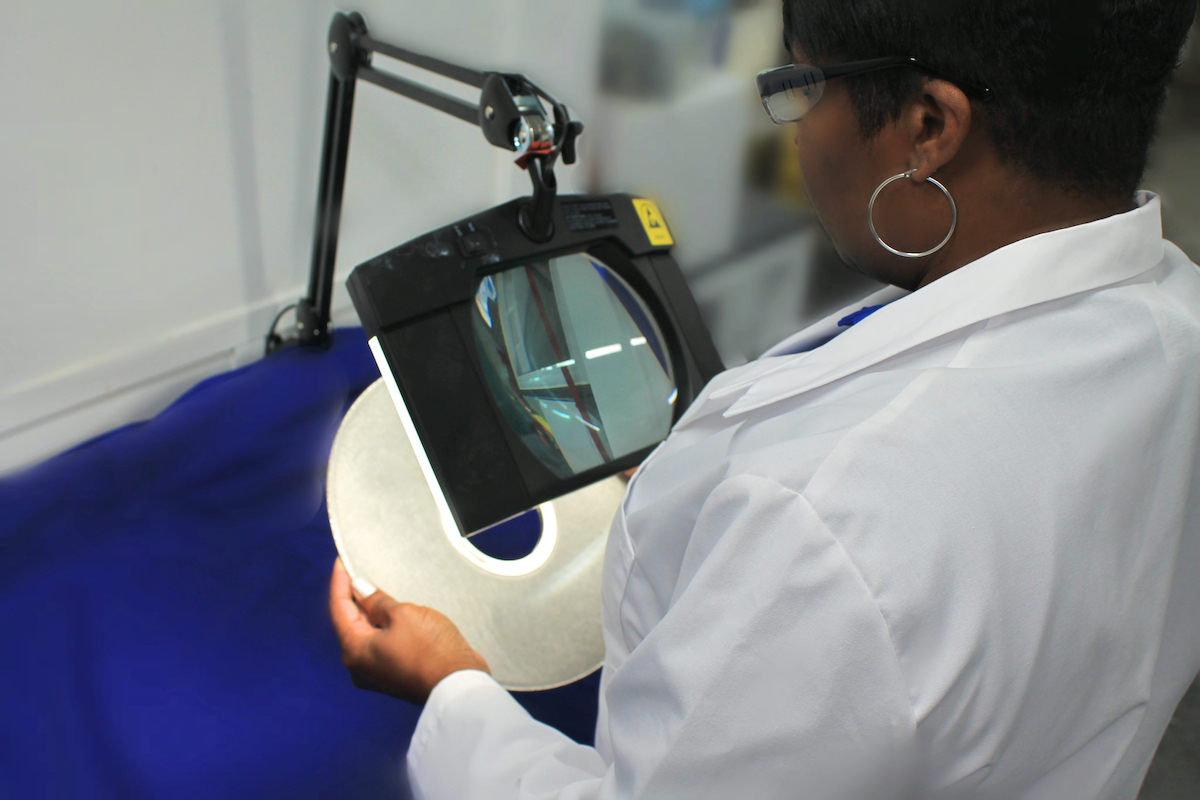

Carolina Filters is dedicated to providing the most technically precise filtration services available.

So how does our filtration evaluation work?

Each filter, component, or part cleaned by Carolina Filters must pass a final test, or series of inspections, for cleanliness and integrity evaluation. For filters, test procedures follow standards that are provided by the end user and the filter manufacturer. For integrity evaluations, our Carolina Filters team members test to standards, such as the ARP901 Bubble Point Test Standard. Additional tests include, but are not limited to wetted air flow testing and dry air permeability.

What we do

Prior to certifying a filter for reuse, Carolina Filters performs a multi-layered evaluation process including visual inspections, wetted testing under isopropyl alcohol or water, and as needed, dry air permeability testing. Customized testing reports collate data in a user-friendly manner to allow the end user to document and quantify the level of cleanliness and integrity of their component.

|

Carolina Filters maintains a detailed database that records and stores all final test data for each component tested. Filters and associated parts are serialized in-house, and each filter will carry its serial number throughout the life cycle of that part. This data also becomes a benchmark for future testing services or evaluation needs. Each test report is customized to the need of the end user. Most reports contain some or all of the following information:

|

|