Cleanliness Testing for Metal Filters

Carolina Filters developed testing to quantify the cleanliness of porous metal filters to be used in parallel with integrity testing. Dry air ΔP Testing uses the pressure drop created across a porous metal cartridge to quantify restriction related to pore structure and embedded contamination within the media matrix.

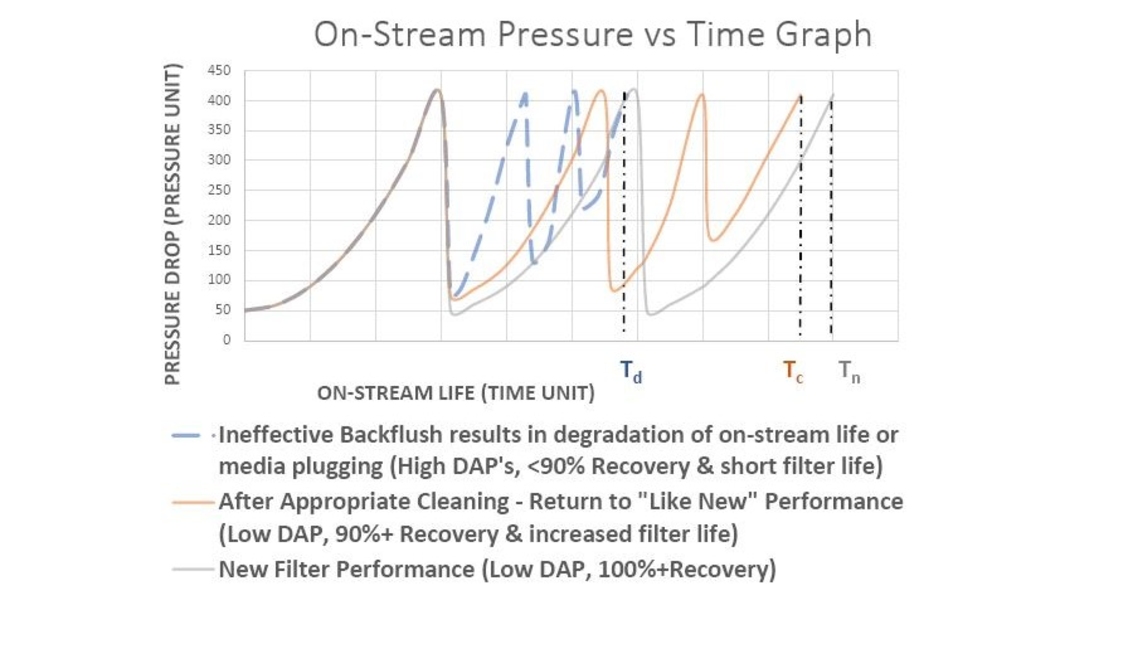

This test can be used to show percent recovery across a filter, as well as confirmation that no contaminants have been left behind. The chart above represents three situations and their pressure drop data. Each time a curve peeks, this signals the back flush process.

The grey curve represents a new filter. Time between each back flush cycle is far apart and pressure is able to be returned to the original starting position each time (around 50 on this chart) until it reaches the end of its life (back flush process will not lower the pressure due to fouling) and it needs to be cleaned.

The orange curve represents a properly cleaned filter, where time between each backflush cycle is less than the new but still a decent distance apart, pressure is able to be lowered, and time until the filter needs to be cleaned is only slightly less than a new filter.

The blue curve shows how a dirty filter or an improperly cleaned filter behaves. In this case, time between back flush cycles is short, the filter pressure is not successfully lowered, and time until the filter needs to be cleaned is drastically lowered.